Advancements in Steering System Manufacturing Efficiency

world777, 11xplay pro, betbook247 app login:Advancements in Steering System Manufacturing Efficiency

Steering systems play a crucial role in the operation of any vehicle, ensuring that drivers can control their vehicles safely and effectively. As technology continues to evolve, so does the manufacturing process of steering systems. Advancements in steering system manufacturing efficiency have led to improved performance, durability, and overall customer satisfaction. In this blog post, we will explore some of the latest innovations in steering system manufacturing and how they are revolutionizing the automotive industry.

Improved Materials and Design

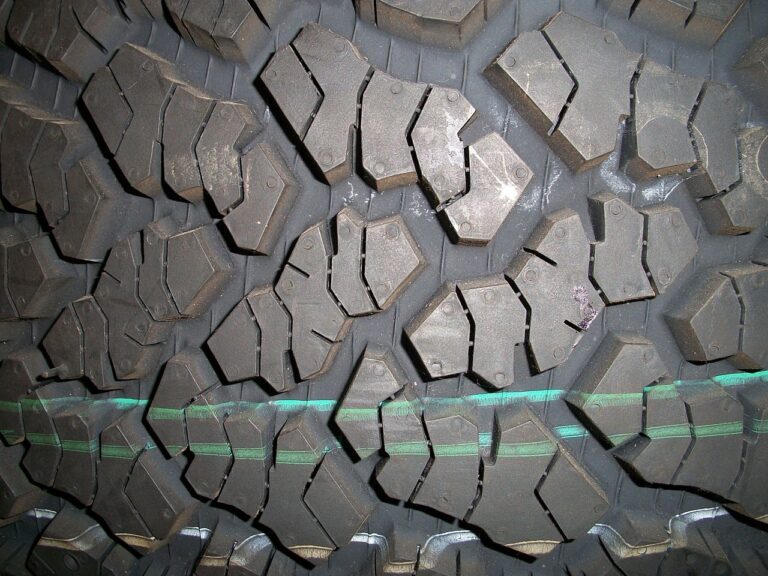

One of the key advancements in steering system manufacturing efficiency is the use of advanced materials and design techniques. Manufacturers are now able to create steering components that are lighter, stronger, and more durable than ever before. This not only results in better performance but also contributes to overall fuel efficiency and reduced emissions.

Advanced materials such as carbon fiber, aluminum, and high-strength steel are being used to create steering components that are not only lighter but also more resistant to wear and tear. In addition, innovative design techniques such as computer-aided design (CAD) and simulation tools are helping manufacturers optimize the shape and structure of steering components for maximum efficiency.

Precision Manufacturing Processes

Another key advancement in steering system manufacturing efficiency is the use of precision manufacturing processes. Modern manufacturing techniques such as CNC machining, 3D printing, and robotic automation have revolutionized the way steering components are produced. These technologies allow for greater precision, consistency, and speed in the manufacturing process, resulting in higher-quality products and faster production times.

Robotic automation, in particular, has been instrumental in improving efficiency in steering system manufacturing. Robots can perform repetitive tasks with incredible speed and accuracy, leading to fewer errors and increased productivity. This not only reduces production costs but also ensures that steering components meet the highest quality standards.

Integration of Smart Technologies

The integration of smart technologies is another major advancement in steering system manufacturing efficiency. Manufacturers are now incorporating sensors, actuators, and other smart devices into steering components to enhance performance and reliability. These smart technologies allow for real-time monitoring of steering system performance, predictive maintenance, and even autonomous driving capabilities.

For example, electronic power steering systems (EPS) use sensors and actuators to adjust steering assist based on driving conditions, resulting in smoother steering and improved fuel efficiency. Similarly, lane-keeping assist systems use cameras and sensors to help drivers stay within their lane, reducing the risk of accidents. By integrating smart technologies into steering systems, manufacturers are able to improve safety, comfort, and overall driving experience.

Environmental Sustainability

In addition to improving performance and efficiency, manufacturers are also focusing on environmental sustainability in steering system manufacturing. With increasing concerns about climate change and air pollution, automakers are under pressure to reduce their carbon footprint and minimize waste in the production process.

One way that manufacturers are addressing these challenges is by using recycled materials in steering system components. By reusing materials such as aluminum, steel, and plastic, manufacturers can reduce the environmental impact of production and decrease the amount of waste sent to landfills. In addition, energy-efficient manufacturing processes and renewable energy sources are being employed to further reduce the carbon footprint of steering system manufacturing.

FAQs

Q: What are some of the key advancements in steering system manufacturing efficiency?

A: Some key advancements include the use of advanced materials and design, precision manufacturing processes, integration of smart technologies, and a focus on environmental sustainability.

Q: How are smart technologies being integrated into steering systems?

A: Smart technologies such as sensors, actuators, and cameras are being used to enhance performance, reliability, and safety in steering systems.

Q: Why is environmental sustainability important in steering system manufacturing?

A: Environmental sustainability is important to reduce the carbon footprint of production, minimize waste, and address concerns about climate change and air pollution.

In conclusion, advancements in steering system manufacturing efficiency are transforming the automotive industry, leading to better performance, durability, and environmental sustainability. By leveraging advanced materials, precision manufacturing processes, smart technologies, and a focus on eco-friendly practices, manufacturers are able to produce steering components that meet the highest quality standards while minimizing their environmental impact. As technology continues to evolve, we can expect even more innovations in steering system manufacturing that will further improve safety, comfort, and efficiency on the road.